Fenner Dunlop provides hardworking people with the hardest working, safest, and longest-lasting conveyor belts on the market. For over 150 years, our engineers & technicians have been on the front line in developing and refining conveyor belts that assist our customers in maximizing valuable uptime and revenue.

We understand that conveyor belts must be able to withstand an enormously wide range of physical and environmental conditions, as well as increasingly tough safety demands, which is why we manufacture our own conveyor belts in our North American facilities. This allows us to ensure the integrity of our conveyor belting by providing focused attention to each belting order. Our manufacturing process starts at our state-of-the-art, climate-controlled 320,000 square foot weaving facility in Lavonia, Georgia. All Fenner Dunlop carcasses are woven under precise monitoring with yarn we twist in-house. Production is then passed on to and completed at our manufacturing plants in Port Clinton, Ohio, Toledo, Ohio and Bracebridge, Canada.

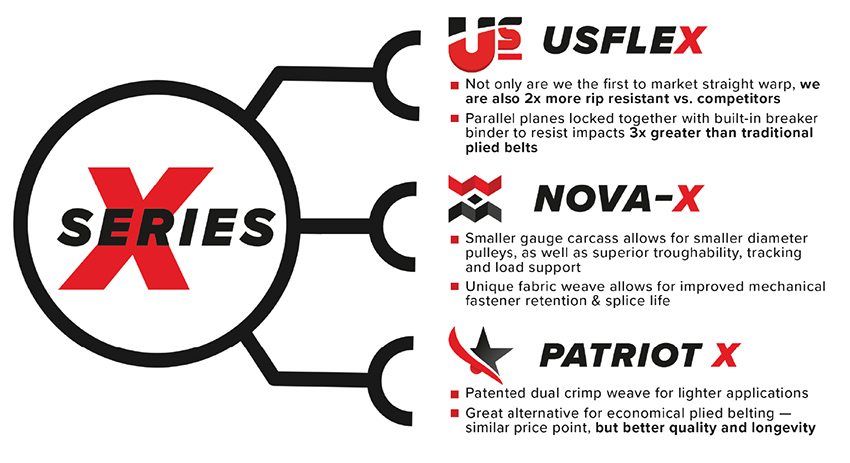

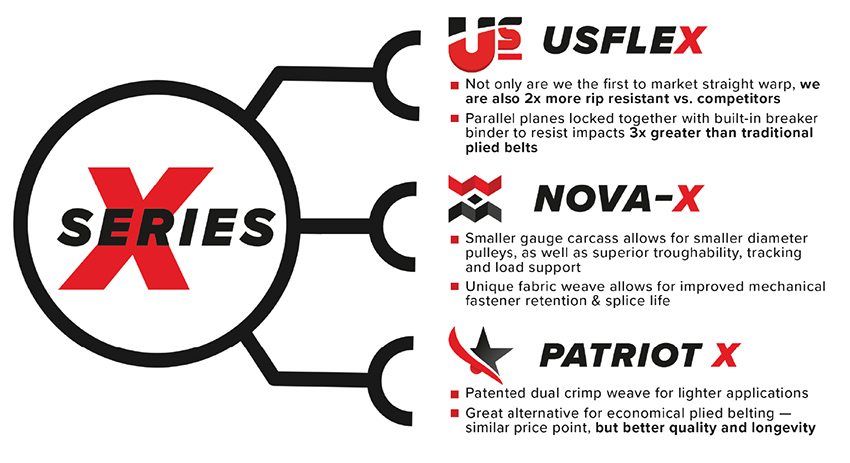

We offer the best combination of carcasses and cover compounds on the market for your peace of mind. Our X Series, Plylok Group and Specialty Group product families offer the right belt carcass options for your specific bulk material handling needs. Plus, our cover compounds cover any applications using materials that not only result in a more robust product, but also a better environmental footprint. Some of the cover compound options we offer include cut/gouge, abrasion, cold-resistant, heat resistant, oil resistant, low extraction, non-stick and power saver.

Fenner Dunlop is proud to partner with IBT Industrial Solutions. By joining Fenner Dunlop’s and IBT’s impressive 220 years of combined industry experience and knowledge, we can better serve the Central and South-Central United States industrial markets through this partnership. We are ready to help you succeed in your specific bulk material handling operations! Visit www.fennerdunlopamericas.com to learn more.

Keep up to date on product news and latest offers.

Copyright © 2024 All rights reserved by IBT Industrial Solutions