Screw conveyors don’t always work best for every application. In fact, switching to a drag conveyor can sometimes save you a significant amount of money over the life of the conveyor.

“There’s no one conveyor that can solve every problem,” said John Coxon, Bulk Handling Product Specialist at IBT Industrial Solutions. “But by analyzing your operations, you can often save money by switching to a different conveyor.”

How Do Drag Conveyors Improve Throughput?

They reduce degradation.

Drag conveyors use a special paddle to push product through the system—so they don’t “grind up” the product. This makes them ideal for use with corn, wheat, and rice.

They use less power—saving you money on electricity.

“Screw conveyors require more horsepower to operate on a daily basis,” Coxon said. “So even though a screw conveyor may be less expensive upfront, a drag conveyor actually pays for itself over the life of the equipment with lower energy costs.”

They move product faster.

Since a drag conveyor uses less horsepower (and energy), it can actually move product faster than a screw conveyor—increasing your overall throughput and capacity.

4 Common Types of Drag Conveyors

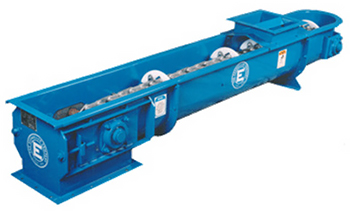

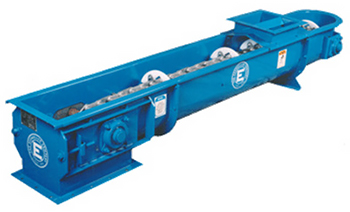

IBT frequently partners with Essmueller to provide complete systems—plus a wide variety of replacement parts—for bucket elevators, drag conveyors, and turnhead distributors. Essmueller has been providing bulk material handling equipment since 1878, and has over 130 years of experience in the field.

The company’s 4 most common types of drag conveyors include:

- Flat-bottom drag conveyors

- Round-bottom drag conveyors

- Heavy duty drag conveyors

- Incline drag conveyors

Choosing the Right Conveyor

IBT’s bulk handling specialists can analyze your operations and help you find the best conveyor to lower your energy bill, speed up production, or even save room in your facility. They can also find a solution that fits into your current footprint.

When a customer is looking for a better conveyor solution, Coxon typically asks the following questions:

- What type of material are you moving?

- How heavy is the material?

- How many bushels per hour do you process?

- Is the conveyor system running on a horizontal, or an incline?

“90% of the time, if you tell me the type of conveyor you’re currently using—plus the type and weight of material you’re moving—I can tell you if there’s a better solution out there that will save you money,” Coxon said.

Could a drag conveyor improve YOUR operations?

IBT Industrial Solutions can help you decide if a drag conveyor could reduce your energy costs—and improve your throughput. For a FREE assessment, contact your local IBT branch.