Are you concerned about your staff unloading heavy, 50-pound bags from full pallets? IBT’s Custom Pallet Unloading System can do the heavy work for you—and prevent injuries along the way.

What Is an Automated Pallet Unloading System?

Automated pallet unloading systems are a great alternative for loading and unloading pallets in a manufacturing or factory setting, as they can help increase workplace safety. By leaving the heavy lifting to an automated system, companies can further their efforts to prevent the potential of worker injury.

These systems work by providing two different bays–the first bay is where the pallets are loaded manually, such as with a forklift, while the second bay is where the pallet is unloaded. Once the pallet has been loaded onto the second bay, a grabber takes hold of it and swiftly moves it to the assembly conveyor line.

Not only does pallet loading and unloading equipment improve workplace safety, but it also increases assembly line productivity, making it a lucrative resource for your warehouse.

4 Benefits of Pallet Unloading Systems

Our equipment and system options at IBT come with a number of benefits to ensure your assembly line is effective, and your manufacturing efforts are profitable.

1. Handles Loads Up to 4,000 pounds

IBT’s Pallet Unloading Systems are designed to handle loads up to 4,000 pounds. It uses a unique conveyor system to receive pallets from a forklift—and prevent ergonomic stress.

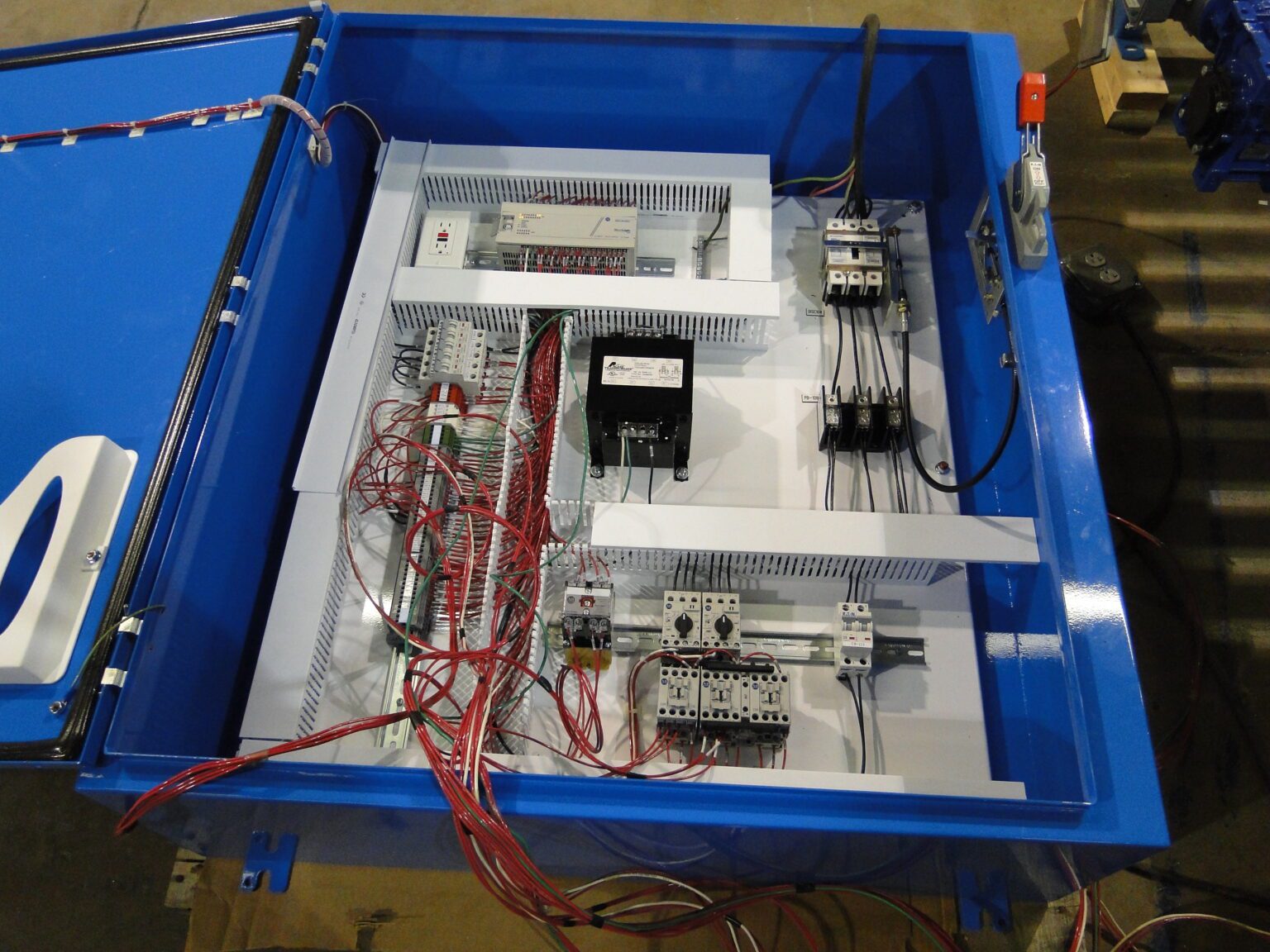

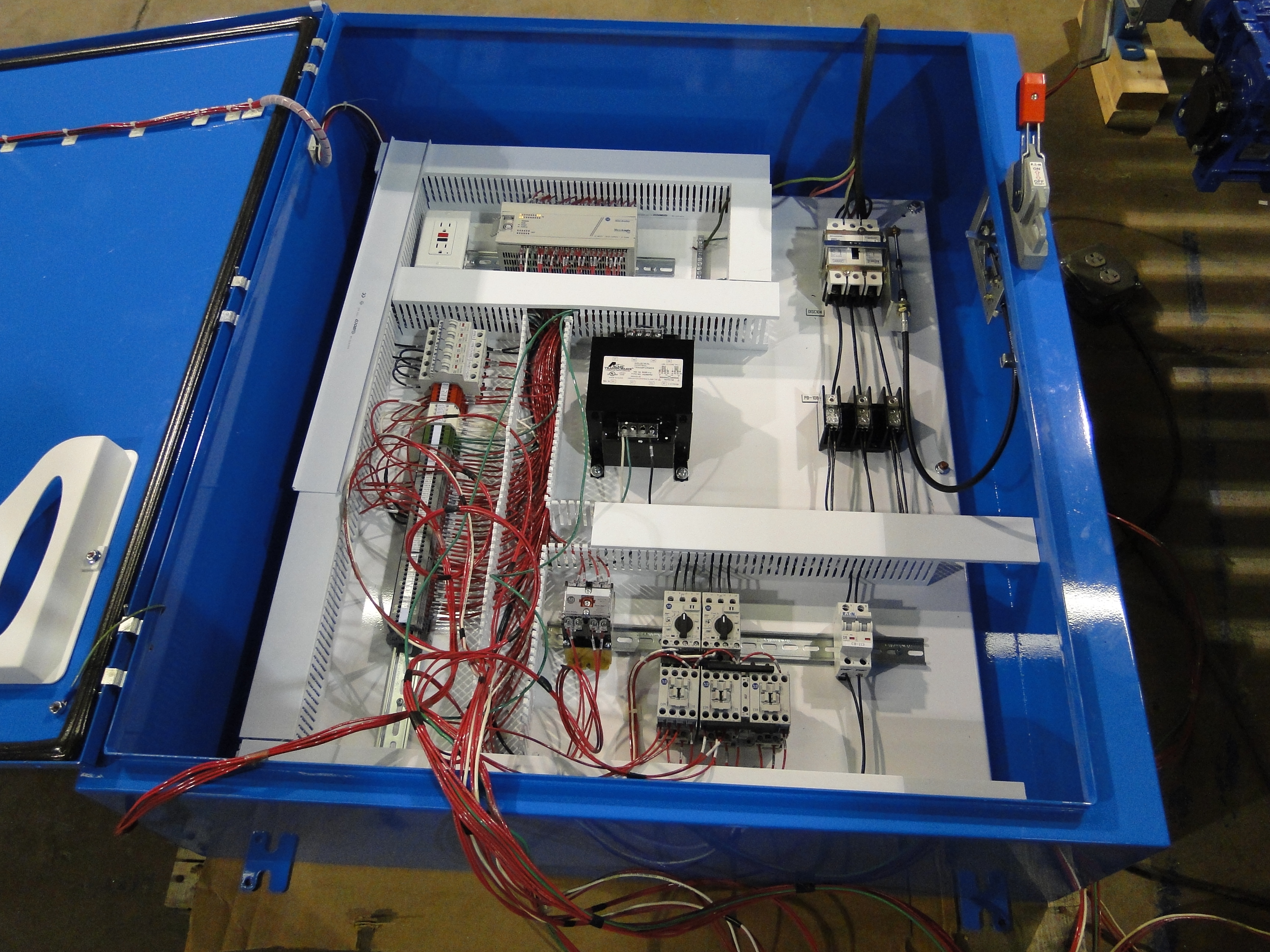

Our Custom Pallet Unloading Systems include:

- Pallet Conveyors: includes a 25 CRR chain driven live roller powered infeed conveyor and a 25SR gravity roller discharge conveyor.

- Scissors Lift: Comes with a manual rotating turntable base.

- Pushbutton Controls: Designed for easy operation by the worker.

- Photo Eye: Ensures there is no pallet on the scissors lift, for safety reasons.

2. Simple, Pushbutton Operation

When a full pallet of parts is loaded onto the infeed conveyor by a forklift operator, the operator simply presses the “Index In” button to move the pallet forward onto the scissors lift.

Once the pallet is in position, and the operator begins to remove parts, he or she can raise the scissors lift to a comfortable working height with a foot switch.

After one side of the tote is empty, the operator can then unload the other side by releasing the turntable lock with a footswitch, then manually spinning the turntable.

When all parts have been removed from the pallet, the operator then lowers the scissors lift and rotates the conveyor into the discharge and locked position.

When the conveyor is clear, the operator simply presses the “Index Out” button, and the empty pallet comes off the scissors lift.

Read More: Throughput Doubled, Zero Increase in Labor

3. Multiple Safety Features

The IBT Custom Pallet Unloading System is equipped with three safety features:

- Turntable Limit Switch: Senses that the turntable is in the locked position.

- Scissors Lift Limit Switch: Senses that the scissors lift is in the down position, so the full tote can be conveyed onto the scissors lift conveyor.

- Photo Eye: Ensures that no pallet is on the scissor lift.

4. Customized for Your Workspace

“This system is custom-designed by the IBT Material Handling and Systems Integration group,” said Jim Boatright, Director of Conveying Systems at IBT. “This allows us to make adjustments to this standard design to meet any customer’s unique needs.”

For example, custom pallet unloading systems can easily be reversed to make a pallet loading station, Boatright said. “Or it can easily be integrated into your plant’s existing control system,” he added.

Optional Features for Pallet Unloading Equipment

This system can also be supplied with an infeed conveyor, which allows multiple full pallets to be accumulated with zero back pressure to the scissors lift—freeing up the forklift truck driver to manage multiple job tasks.

Optional upgrades include:

- Power rotated turntable

- Powered discharge conveyors

- Complete gravity conveyor system

Read More: New Sorter System Helps Berry Plastics Reduce Errors

Request a Free Evaluation or Learn More

Your one-stop industrial shop is also your conveyor expert. Schedule a free consultation today or contact IBT’s Director of Conveying Systems Jim Boatright at (913) 261-2116 to learn more.