A Monitoring Technology That Sets New Standards

Safety has top priority in the chemical industry. This is because flammable media are used in hazardous areas, which are transported by means of pumps. Reliable dry running protection is a must. With SIMOCODE pro, Siemens delivers an innovative monitoring technology that breaks with conventional pump monitoring – and redefines dry running protection in hazardous areas.

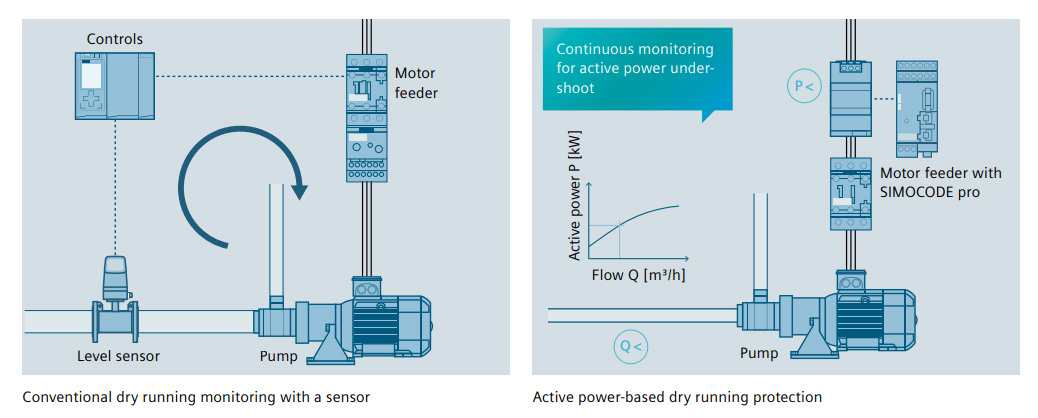

A novelty in this field until now, centrifugal pumps in hazardous areas of the chemical industry have been protected from dry running by special sensors. However, these sensors are susceptible to faults and require intensive maintenance. With the active power-based dry running detection for centrifugal pumps in hazardous areas, Siemens introduces an absolute novelty to the market.

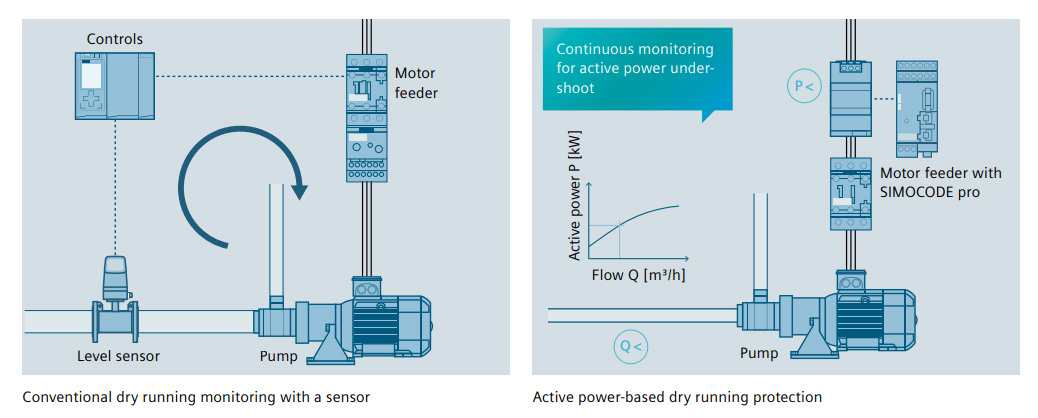

Whereas conventional dry running detection is performed by a dry running sensor via the process control to the pump, SIMOCODE pro monitors the status of the pump via the active electrical power consumption of the pump motor. This eliminates the need to install additional monitoring devices or sensors to detect dry running of the pump. The result: You ensure reliable explosion protection in accordance with ATEX and IECEx criteria and save costs and time for commissioning and maintenance.

Your Benefits Through Active Power-Based Dry Running Protection

Earlier Fault Detection

- Direct conclusions concerning the flow rate can be drawn from the active power consumption of the pump motor

- Reliable prevention of dry running of the pump and therefore less damage to the pump

Cost and Time Savings

- No maintenance effort due to the elimination of mechanical wear of the sensors

- No additional sensor required

Reduction of Hardware

- No need for additional sensors and mechanical components

- Simplified engineering

Reliable monitoring of the system

- Compliance with ATEX and IECEx criteria

- Reliable and automatic pump switch-off in the event of inadmissible operating conditions

The Technology Behind Active Power-Based Dry Running Protection

SIMOCODE pro enables dry running protection of centrifugal pumps through active power monitoring and motor switch-off in compliance with the Ex b type of protection. This applies to centrifugal pumps with progressive flow characteristics, which are also suitable for pumping flammable media and are installed in hazardous areas. The amount of active power allows conclusions to be drawn about the flow rate in the pump. If the flow rate decreases, the active power consumption of the pump motor also decreases. If the active power, and thus the flow rate, falls below a minimum value, the pump is switched off automatically

When determining the limit values to be monitored, the user is supported by a menu-guided teach-in process in the engineering software. Sensors that are usually used to monitor dry running of the pump are no longer required. The active power is detected via special current/voltage detection modules which are approved for use as monitoring devices to protect pumps installed in hazardous areas against dry running.

Learn More About SIMOCODE Pro From IBT’s Electrical Group

IBT Industrial Solutions has a dedicated team of electrical product specialists who have been consulting customers on every aspect of electric motors, and helping them solve their toughest electrical problems, since the 1970’s. Their diversity of skills, expertise and wealth of experience is what makes IBT stand out among our competitors. From reducing energy costs, preventing motor and drive failures, to getting more life out of your current machinery━and everything in between━this team is always up for the challenge. If you’re looking to minimize downtime and become more productive in your operations, contact Jon Prince, IBT’s Electrical Group Director, or give us a call at 913-677-3151 to learn more.