Keep your food and beverage processing perfectly within motion by improving your roller chain performance. The latest innovative conveyor solutions can help you meet the industry’s ever-changing demands when it comes to uncompromising standards for performance and sanitation. From washdown-ready and corrosion-resistant materials to decreasing contamination risk to increasing your processing efficiency, the next generation of roller chains can solve your unique needs in an industry with the most stringent environment.

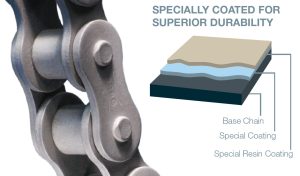

Preserve Tensile Strength with Corrosion- and Chemical-Resistant Coatings

In the food and beverage industry, chains that can resist corrosive environments for longer periods, offer environmentally friendly solutions, comply with RoHS requirements, and are not manufactured with hazardous elements are absolutely essential.

Extend Wear Resistance with Lube-Free Chains

Maximize conveying performance for your food and beverage or food packaging needs with lube-free operations that provide clean applications and ultimate peace of mind. For machines and conveyed materials that need to be free from contact with oil, lube-free chains provide the perfect solution, as they stay cleaner longer, reduce product contamination, and minimize overall maintenance and replacement costs.

Products like the Lambda® Chain from Tsubaki use improved oil-impregnated sintered bushings and NSF-H1 food-grade lubricant to help stabilize quality, improve roller chain performance, and increase wear resistance for long-lasting life. This allows your system to increase energy and labor savings while decreasing downtime.

Enhance Dynamic Performance with Sealed Joint Technology

Protect your system against the harshest environments with sealed joint technology that will protect your bearing areas from the impeding infiltration of foreign matter. The proper seal materials reduce the risk of premature elongation, joint lockage, and dry cavitation, which will significantly increase the effectiveness of a roller chain’s performance and extend its life.

The SJ3™ Series Engineering Class Chains from Tsubaki offers an innovative labyrinth structure made up of three distinct seals, including a barrier, polymer face, and a stainless steel inner ring. With a combination similar to this product, your system will be able to hinder the progression of aggressive fine particulate and enhance its overall dynamic performance.

Material types that would benefit the most from sealed joint technology include:

- Grain & Seeds

- Sugar/Bagasse

- Potash & Fertilizers

- Pet Coke

- Coal

- Gypsum

- Clay

- Fly Ash

- Cement/Clinker

Discover the Possibilities with Tsubaki Conveyor Solutions

Revolutionizing the latest generation of high-quality, long-lasting ANSI roller chains, Tsubaki offers a wide range of premium products that can improve your food and beverage processing or food packaging, including the Neptune® Chain, Lambda® Chain, and SJ3™ Series Engineering Class Chains.

Find Your Roller Chain Solutions on ShopIBT

If you’re ready to upgrade your power transmission and conveyance applications, visit ShopIBT to access special pricing on the newest generation of innovative Tsubaki roller chains.

If you’re in need of a custom solution or would like to learn more about optimizing your plant, contact us today or give us a call at 913-677-3151, and our team of experts will provide you with the support you need.