Common Gear Problems

Sometimes your gear just isn’t working as well—or as long—as you’d hoped. It fails too quickly or doesn’t fit well into your operation. Maybe your steel gear can’t stand up to a wet environment. Or you might have an old gear that’s no longer in production. Perhaps you need something totally new for your machine and you can’t find the right solution anywhere.

Introducing made-to-order (MTO) gears, sprockets, and sheaves from Martin Sprocket & Gear. Martin custom-made gears, sprockets, and sheaves are produced for a variety of industries, in any size—from palm-sized gears to large sprockets that fit a 15 ft. drum.

“If it’s round and has teeth, there’s a pretty good chance we can produce it,” said Jeff Weaver, District Manager of the Kansas City facility for Martin Sprocket & Gear. “We can custom-produce 1 piece or 1,000 pieces, depending on what you need.”

More: You Get What You Pay For

Creating a Custom Gear

To order a Martin custom-made gear, sprocket, or sheave, the customer first provides a sketch, photo, or sample. The Martin team then works with IBT Industrial Solutions to create a design and make an estimate.

“It can even be a drawing on a cocktail napkin,” Weaver said. “People drop off their samples with their IBT rep or with us, and we give them a quote for an estimate. It’s that simple.”

Once the estimate is approved, IBT coordinates the final design of the gear with Martin Sprocket & Gear—including exact diameter, thickness, preferred material, and finish. The IBT team then follows the process through production and delivery.

“The made-to-order products are very popular,” Weaver said. “More than 40% of our business with IBT is now an MTO product.”

More: HTR & HTRC Synchronous Belt Drive System

When to Buy a Made-to-Order Gear or Sprocket

Weaver said that most people look for a made-to-order gear when they need better performance from a gear, or when they need it to fit into a more compact design.

“If your sprocket is failing every 2 months, then something isn’t right,” he said. “We can look at creating a made-to-order sprocket with the same size and shape, but a more durable material or finish, to make it last 5 to 10 years.”

Customers also want to simplify their systems by integrating parts. For example, many customers want to combine a sprocket set and a gear set into one part, which reduces failures, Weaver said. Or they want to convert to a plastic gear that works better in a wet environment, such as a wastewater treatment plant.

More: Guide to Chain

Midwestern Manufacturer Uses Custom Couplings to Reduce Wear on Seals

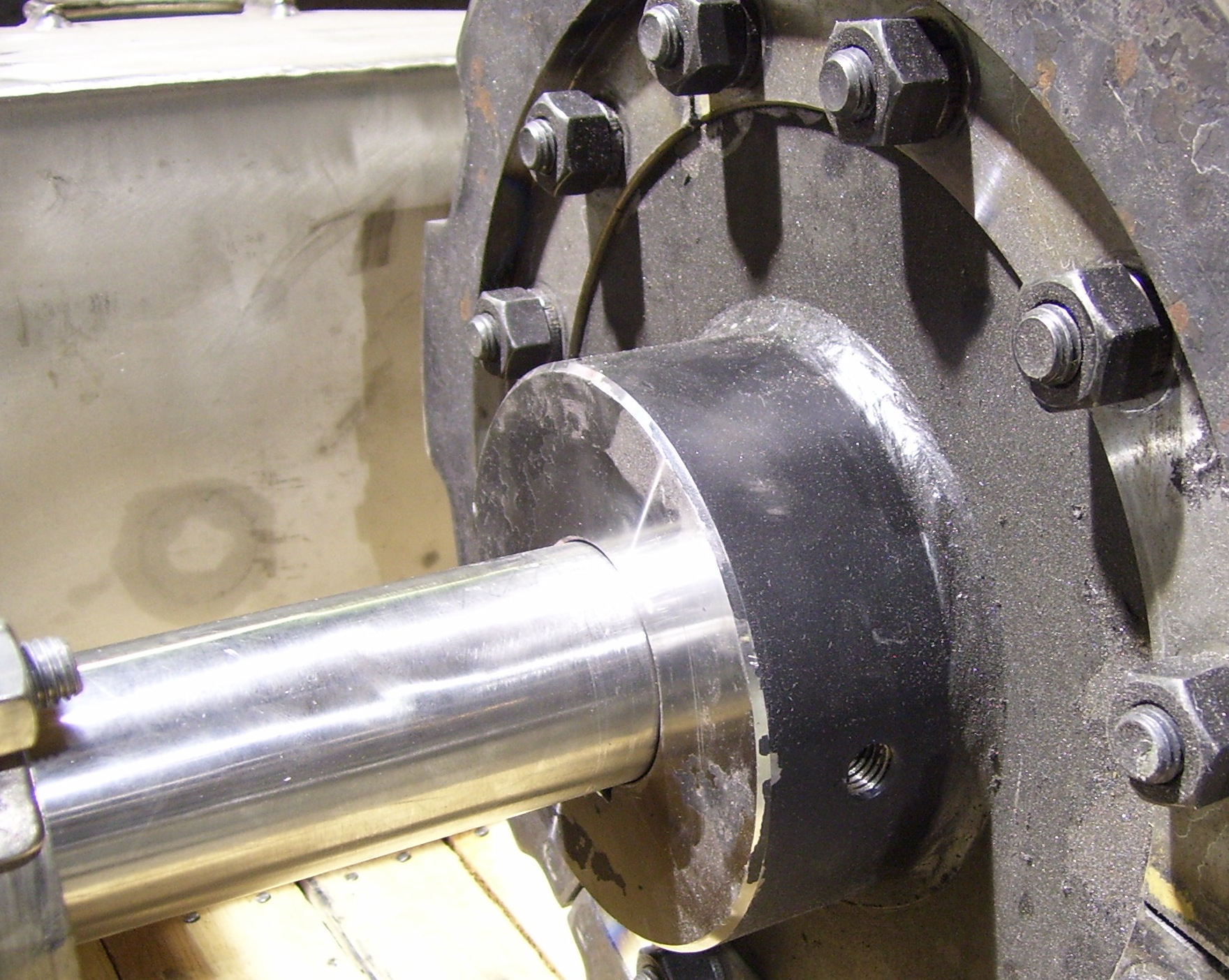

One Midwestern manufacturer, located in Kansas, routinely works with IBT and Martin Sprocket & Gear to order new couplings with extended hubs. They use the custom-designed extended couplings to eliminate the jackshaft in their roll-forming system with multiple stations.

“This essentially eliminated the wear on our seals that is caused by the centrifugal force of the jackshaft,” the buyer said.

The company also orders sprockets with special bores. IBT has been their distributor for Martin Sprocket & Gear special orders for several years, facilitating the overall manufacturing process and delivery.

“IBT and Martin deliver like clockwork,” he said. “We routinely get sprockets rebored and shipped the same day, which is an enormous service to us and especially to our customers.”

More: A Whole New Approach to Conveyor Systems

Questions to Ask

Considering buying a custom-made gear, sprocket, or sheave? Weaver recommends asking the following questions:

- Life expectancy—Does the gear continue to function as expected?

- Demand—Has your demand on the gear increased significantly over the years?

- Reducing parts—Would it help operations to combine several moving parts into a single part?

- Smaller footprint—Do you need a smaller, more compact design?

- Wear—Do you see evidence of wear on your gears?

Get a Martin custom-made gear, sprocket, or sheave

Call Tim Zerger, IBT’s Business Group Director for Bearings, PT & Gearing at 913-261-2140 or tim_zerger@ibtinc.com.