IBT’s Industrial Maintenance Technologies group (IMT) is equipped with a new system to help diagnose unseen problems with your manufacturing equipment. This system is designed to help you find unknown issues with your equipment before it fails by using motion amplification.

IBT’s Motion Amplification

IBT’s Motion Amplification

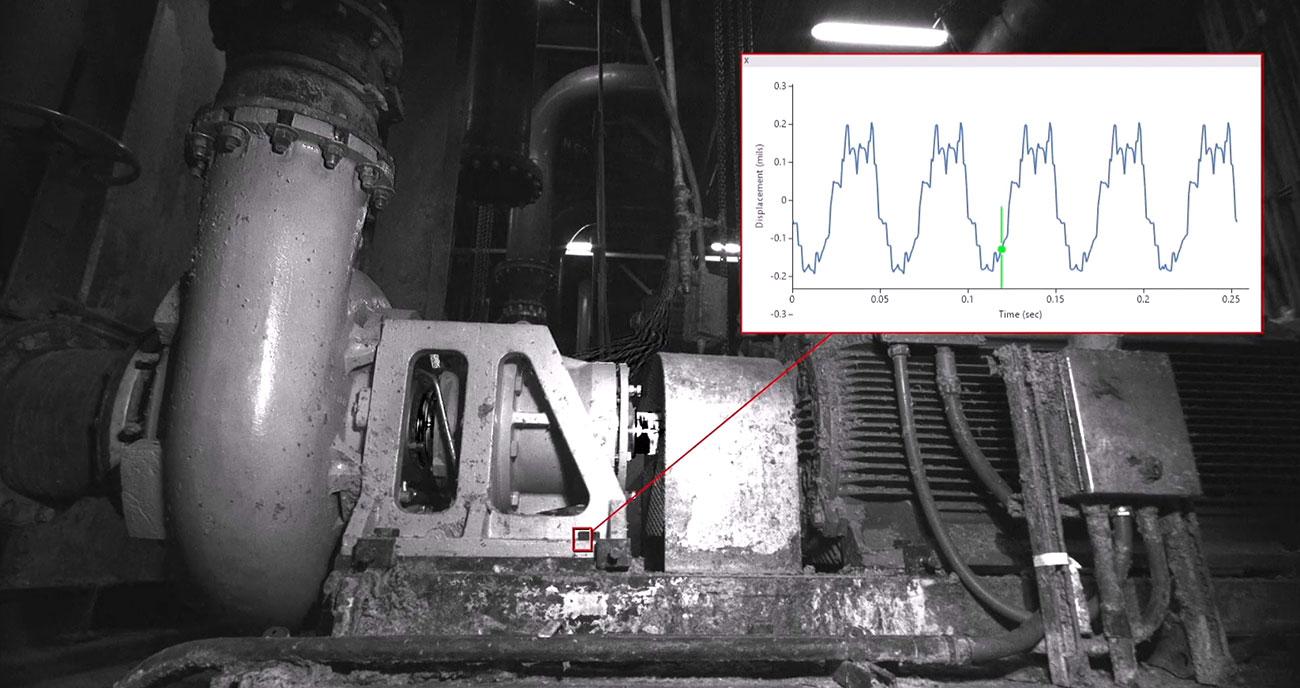

IMT is now utilizing an Iris M motion amplification camera system from RDI Technologies. Motion Amplification uses each pixel like a vibration transducer. This camera allows IMT to film your equipment in use, analyze the equipment, and help solve unforeseen issues with your equipment. The camera system detects looseness, excessive misalignment, structural weakness, cracking, and other causes of amplified vibration. It helps detect machines running in resonance or vibrating excessively.

Preventative maintenance is always more cost-effective than downtime!

The team can analyze:

- Rotating equipment

- Piping

- Conduit

- Silos

- Structural members (buildings, equipment, and pumping stations)

Issues that can be visualized:

- Piping vibration

- Reciprocating engine and compressor motion

- Unbalance

- Misalignment

- Soft foot

- Structural looseness

- Resonance

- Structural cracks

- Drive transmission faults, belts, chains, couplings, Cardan shafts

- Duct and vessel wall deflections

- Structure stiffness and support

- Torsional twisting, bending, and flexing

- Excessive transient loading

- Ineffective damping

- Vibrating screen motion analysis

- Oscillating motion analysis

- Cavitation, hydraulic, and aerodynamic forces

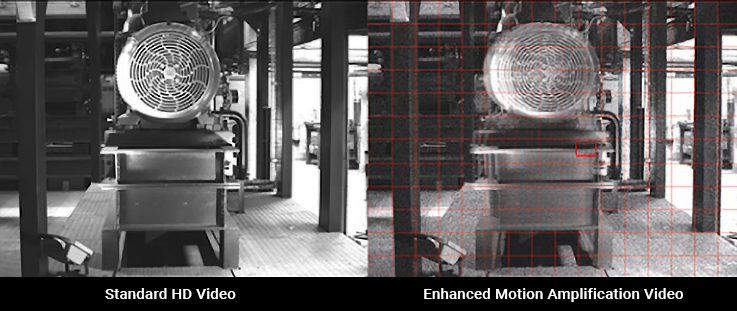

After filming, the camera system can produce side-by-side videos of the amplified motion next to a regular video. (see below image) This helps everyone see the affected areas of excess vibration or motion.

Motion Amplification System in Use

Recently IMT took the camera to a client’s facility to analyze some newly installed pumping equipment. This is brand new equipment with no known issues. The pumps displayed no errors or excess vibrations. The piping on the wall behind the pumps was moving. The movement was not noticeable with the human eye, but the Iris M camera saw it immediately. The vibration of the pipes was not a critical issue, but the vibration over time would have caused issues with the piping brackets and the extra vibration would eventually lead to the pumps having a shorter operational life. The client added some bracing to the pipes to secure the vibrations from the recommendation of the vibration analysis. The motion amplification camera system did the analysis quickly and efficiently and discovered an issue that no one was expecting to find.

Another instance of IMT utilizing the Iris M camera system included the analysis of a pump. A 3-second video showed that the pump itself was just fine, but one of the pump’s feet was loose. This looseness leads to extra vibrations for the pump and will lead to a shorter operational expectancy for that pump. The solution was a shorter bolt or extra washers and now that pump is secure with no unnecessary vibrations. This is a system that before the analysis had no known issues and the client thought was functioning properly.

The analysis videos are given to the customers at the end of each discovery session.

Learn more from IBT’s Industrial Maintenance Solution Experts

With our years of experience in industrial maintenance, you can rely on IBT for the best solution to your problems. IBT takes pride in your continued operational uptime. Let us help you continue to keep on keeping on! Contact Leo Simbeck, the IBT Industrial Service Manager at (913) 428-2831 to learn more.