Conveyor Idlers

All conveyor idlers are available in a wide range of belt widths to meet customers’ needs.

Order from an array of basic conveyor idlers designed from names like PPI, Douglas and Martin. These styles will not only meet most standard conveyor requirements, but exceed CEMA standards. Additionally, special conveyor idlers can be designed and fabricated for your special applications. IBT will be happy to help you select the right type and combination of idlers to fulfill your conveying needs.

Conveyor Idlers’ Specifications Can Include:

Various Diameters, Tapered Rollers, Rubber Cushion, Impact, Garland/Catenary, Belt Saver Brackets, Polyurethane Rolls, Guide Rollers, Return Roll Guarding, Impact Beds, Stub Rollers, Retro Rolls

CEMA B • CEMA C • CEMA D • CEMA E

CEMA B • CEMA C • CEMA D • CEMA E

Impact Idlers – Choose from our wide selection of idler stylers with the addition of rubber discs built to absorb impact and dissipate shock loads to bearings, idler frames and conveyor structure.

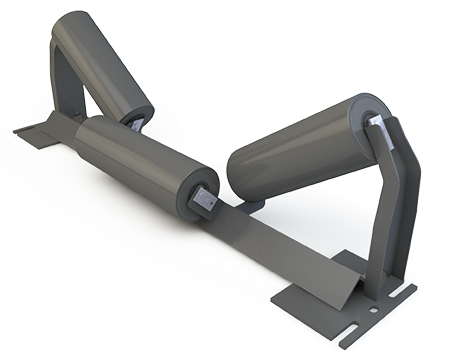

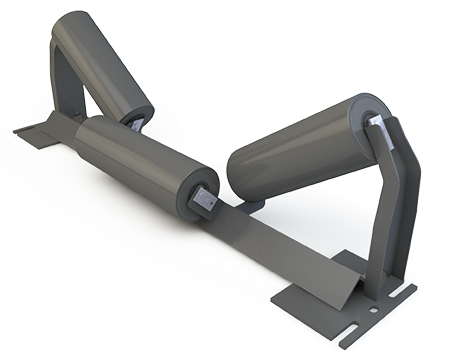

Troughing idlers – Troughing idlers typically contain 3 rolls with wing roll inclinations of 20, 35 or 45 degrees

- Unequal Troughing Idlers – Unequal Troughing Idlers are typically chosen for their lower profile design. This idler lays out the material and allows for easy sorting and separation

- Channel Inset Troughing Idlers – This low profile design is often used on portable equipment or between frame mounting vertical clearances are minimal

- Self-aligning Troughing Idlers – Training Idlers assist in training the belt and protect belt edges from damage caused by misalignment. Available in bi-directional design

- Carrier and Return Idlers – Return idlers support and carry the empty belt on the return side

PPI Grain idler – Designed to protect the lightweight belting that is typically used in the grain industry, PPI’s Grain Idler incorporates an offset center roll design. By offsetting the center roll relative to the wing rolls it eliminates the pinch point, protecting the most expensive piece of the conveyor system, the belt.

Ehrsam Replacements – IBT has worked extensively with PPI in developing the Ehrsam Style Retro idlers now being offered.

About IBT’s Conveying Systems Group

As specialists in the conveying systems field, IBT Industrial Solutions understands the importance of good systems application in achieving optimum efficiency. With our years of experience in providing conveying systems and components, you can rely on IBT for the best solution to your problems. contact Jim Boatright, the Conveying Systems Business Group Director at IBT Industrial Solutions.

INTRODUCING AN UPGRADED ONLINE SHOPPING EXPERIENCE – SHOPIBT!

OFFERING YOU THE BEST PRODUCTS IN EVERY CATEGORY

FROM THE BRANDS YOU CAN TRUST

Discover the benefits of the

FREE IBT Advantage Program

Wondering what makes IBT great?

Don’t just take our word for it.

Get in touch for help and information

Our head office address:

9400 W 55th St, Merriam, KS 66203

Call for help:

(913) 428-2858