Success in food and beverage manufacturing comes down to a micro-moment. As a food manufacturer, your purpose is to help others bring their product and vision to life.

You know the work your customers put into recipe development, sourcing ingredients, marketing, and more. It doesn’t matter if it is a mom-and-pop start-up or a multi-national food corporation; the work, effort, and money your customer has poured into their product all comes down to manufacturing.

A critical point that tends to be overlooked in food manufacturing is the hose used to transfer the product. When taste is everything, you have to be sure you have the right tools to bring that to life. A quality food and beverage industrial hose can make all the difference.

Why Having the Right Food & Beverage Industrial Hose Is Important

Food processing facilities need to meet strict safety regulations, and only Continental makes hose compounded with Microban. Continental Contitech’s hoses are the best products in the industrial hose industry. They offer the most comprehensive line of high-quality products with innovative solutions and are backed by a knowledgeable and thorough host team.

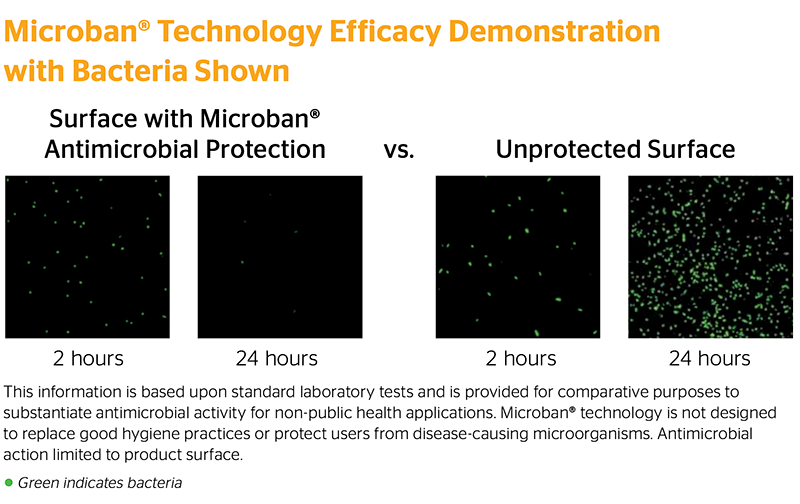

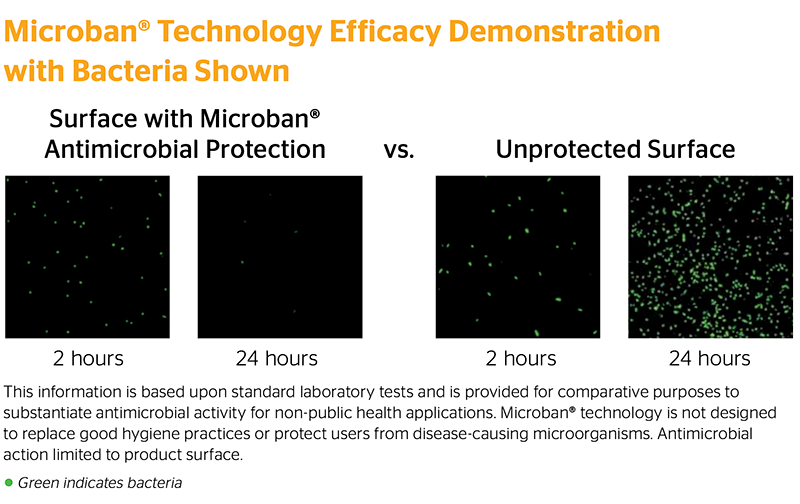

Continental Contitech partnered with Microbran to create a new hose with unparalleled cleanliness. Microban’s antimicrobial technology is widely tested as one of the best available. Contitech Continental’s industrial hoses, combined with Microban’s anti-bacterial technology, have created five lines of food and beverage hoses to inhibit the growth of bacteria, mold, and mildew and ensures 24/7 product protection from product touching the hose surface.

Benefits of Microban Technology

Microban is a revolutionary antimicrobial protection within the hose cover. These food manufacturer anti-bacterial hoses can be used for food processing, dairy, meat packing, bottling, breweries, washing down, and other food processing facilities.

Proven to guard against product contamination, Microban prevents the growth of stain and odor-causing bacteria, as well as mold and mildew on the hose. Microban helps keep your hoses clean between uses with proactive protection that lasts for the life of the product.

Producing the highest quality food products requires clean tools and equipment. Experience these benefits with Microban’s Anti-Microbial ContiTech hoses:

- Experience more protection and boost product safety

- Guard against hose contamination

- Prevent growth of bacteria, mold, and mildew

- Around-the-clock permanent antimicrobial product protection

Poorly manufactured hoses have the potential of augmenting ingredients. With Microban technology, you can rest assured your hoses are honoring the ingredients and flavors of the ingredients you are manufacturing. Not imparting their own taste on them.

Properties of Food-Grade Hoses

The design of a food-grade hose will change depending on the exact application. There are a number of properties that all food-safe hoses have in common:

- Odor Resistance: When working with transferring food, drink, and ingredients, it’s important that hoses and tubing don’t transfer any smells or tastes to the product.

- Abrasion Resistance: These hoses need to stand up to regular use and be resistant to abrasions, which may cause cracking, leakage, or contamination.

- Flexibility: One of the main reasons for using food-safe tubing is the flexibility. Hoses should be flexible and kink-resistant while still offering durability.

- Chemical Resistance: Sanitized hoses benefit from higher chemical resistance than other hoses, making them suitable for food processing.

- Temperature Resistance: Many foods need to be at higher temperatures, and their hoses need to be able to withstand high temperatures.

- Pressure Resistance: To keep up with production, keep a high flow rate, and have the maximum utility, food-grade hoses should be able to withstand higher pressure, which might weaken standard PVC hoses over time.

Food-Grade Hose Applications

Many applications benefit from using a food-safe rated hose. Microban’s food-safe hoses are ideal for:

- Food Industry Applications: This is the main intended use for Microban’s Anti-Microbial hose. The food industry requires hoses ideal for food and drink processing as well as conveying products such as seeds and grains.

- Drinking Water Applications: Anti-microbial tubing is great for conveying drinking water. Everything from drink dispensers in restaurants to drinking fountains in schools benefit from anti-microbial hoses.

- Caravan & Boat Applications: Food-grade hoses are important for filling onboard water tanks for caravan sites, motorhomes, and boats. Odorless and bacterial-free is important for water that will be stagnant for longer durations.

- Animal Farming Applications: Distributing seeds, grain, and other food materials to livestock must be done with a hose that will not spread bacteria and introduce livestock to new threats.

- Aquatic Applications: Some fish require delicately balanced ecosystems, and it’s important not to contaminate their environments when making changes, cleaning tanks, transferring animals, or feeding animals.

Thankfully, IBT’s hose division has a solution for you! Contact us today to learn how Microban’s ContiTech Food Manufacturing Anti-Bacterial Industrial Hoses can benefit your manufacturing processes in the food and beverage industry!